What Are Drape Walls?

These systems Silk carpet cleaning can be customized to fit the specific needs of the project, with a vast array of aesthetic options available including various glass kinds, finishes, and shades. This allows architects to create a special and personalized look for the building while preserving the effectiveness and speed of the prefabrication process. Generally, drape wall systems use a series of benefits to modern building design, offering both functional and visual advantages. Thus, it is necessary for engineers and developers to consider these systems as a practical option for their projects. A curtain wall surface is an exterior covering of a building in which the outer wall surfaces are non-structural, rather offering to protect the inside of the building from the aspects. Since the curtain wall surface façade carries no structural load past its very own dead load weight, it can be made of light-weight materials.

- The big glass panels supply unhampered sights, while the minimal use of architectural assistances develops a smooth and contemporary look that is ideal for high-end jobs.Anodized aluminum frameworks can not be "re-anodized" in position but can be cleaned and protected by proprietary clear finishings to improve look and toughness.Architects like Louis Sullivan from the Chicago College of Style began explore big glass facades sustained by steel structures.These systems can provide improved energy efficiency and insulation, decreasing heating & cooling costs and boosting indoor comfort.They're safeguarded along with one end dealt with onto an external wall and the other end affixed to a concrete base or flooring piece.

What Is A Curtain Wall System's Aesthetic Imprint?

Aluminum curtain walls are among the most typically used products due to their lightweight nature and deterioration resistance. Glass panels, or drape wall surface home windows, are often made use of within the aluminum structure, enhancing all-natural light and offering unblocked sights. In regions like the UK, drape walling UK has actually come to be a preferred construction aspect, as it gives buildings a contemporary visual while adhering to stringent structure criteria.

Natural stone is a very durable material that can hold up against severe weather conditions, making it excellent for usage in areas with high winds, rainfall, or snow. It is likewise resistant to fire, influence, and corrosion, making it a low-maintenance and resilient alternative. They can be created to fulfill a range of aesthetic and useful demands, with a variety of options for glass kind, color, and surface.

Polishing For Drape Wall Surface Systems

Additionally, aluminium sheeting with a silicone polyester coating can be employed. By integrating these confrontings with protecting products like EPS, rockwool, polyurethane, or polyisocyanurate, lightweight infill panels attaining U-values below 0.35 W/m ² K can be generated. As laws come to be more stringent pertaining to building sustainability, integrating these ingenious patterns ensures compliance with future requirements. Building styles that embrace these modern technologies not only fulfill existing requirements but are also gotten ready for advancing regulations.

They're most typical in little buildings with low needed quantities, however complicated problems. Steel framework is making a little a return for polished curtain wall surfaces thanks to advances in product qualities and forming innovation. While steel is naturally hefty, the right system can support bigger wind and glass loads. In the stick curtain wall system, the parts will certainly be set up item by piece on the building website itself.

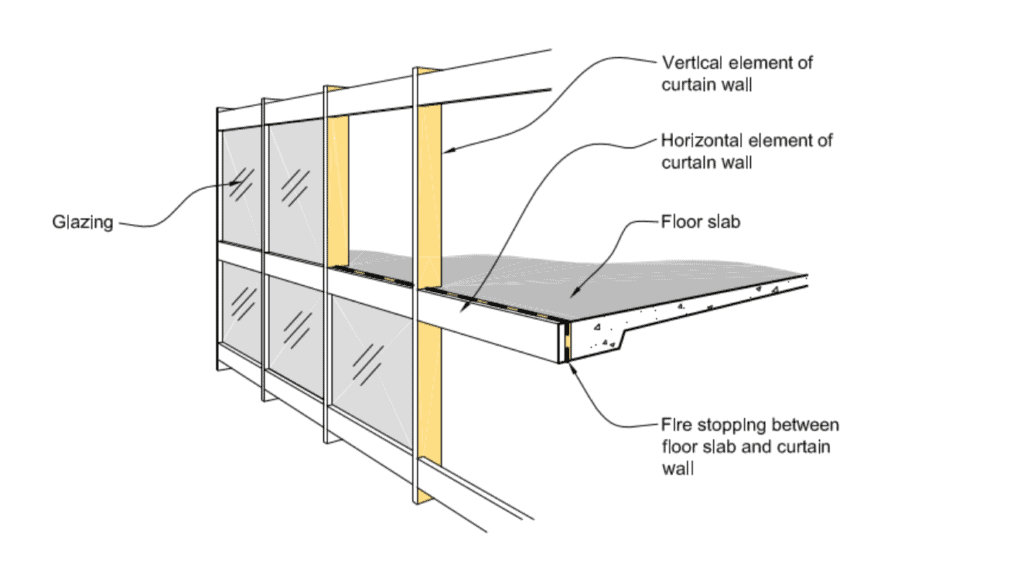

What Is Curtain Wall? Its 2 Systems, Benefits, & Drawbacks

Proper maintenance is necessary for the long life and performance of a curtain wall surface system. Routine examinations, cleansing, and fixing any type of damages or wear and tear are needed. The option of drape wall surface products, such as aluminum structures and sturdy glazing, can likewise affect upkeep requirements. Curtain walls are also with the ability of supporting the internal temperature of a building. This normally entails glazing or shielding the glass panels to decrease heat transfer.

In addition, the cavity between the glass panels can be used for air flow or as a space for shading devices, further boosting the capability of the system. In addition to their power efficiency benefits, dual skin curtain wall surface systems likewise provide exceptional acoustics efficiency. The tooth cavity between the two layers of glass assists to lower noise transmission, making them excellent for buildings found in noisy atmospheres. An additional advantage of point-supported glass curtain wall systems is their adaptability. The large glass panels can be personalized to fit the details demands of the project, with a variety of choices for glass kind, shade, and finish.The use of high-strength glass and steel braces provides excellent resistance to wind and seismic loads, making them ideal for buildings in locations vulnerable to extreme climate condition. Stick-built curtain wall surface systems are a popular sort of outside cladding system made use of in modern-day structure layout. These systems include private parts, such as glass panels and steel framework, that are set up on-site. This permits greater versatility in style and installation, as each part can be tailored to fit the details requirements of the job.